Payment methods accepted

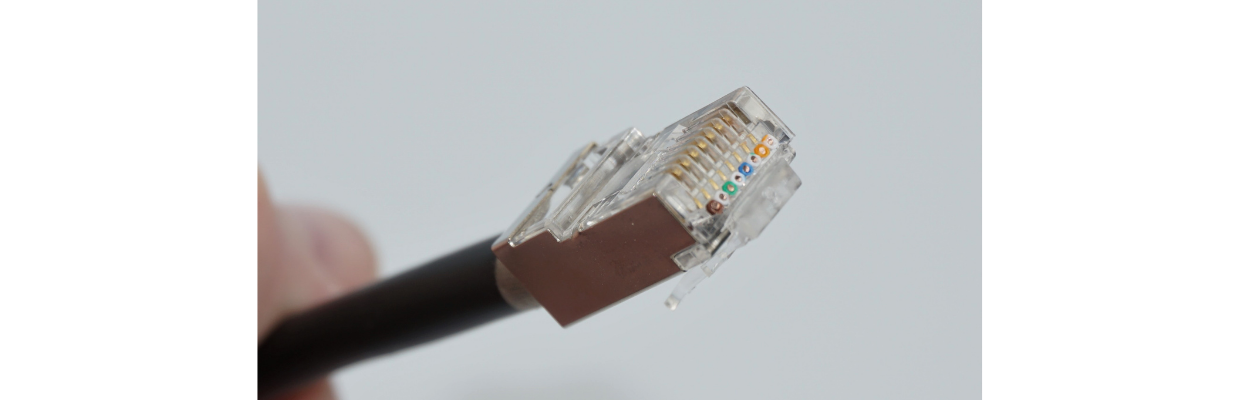

How To: Terminate a Shielded Cat5e Internal Ground Pass Through RJ45 Connector

Written by Don Schultz, trueCABLE Senior Technical Advisor, Fluke Networks Copper/Fiber CCTT, BICSI INST1, INSTC, INSTF Certified

Putting on a shielded RJ45 connector plug can be a challenge for any Category cable. The trick is to understand how the connector works and prepare your Ethernet cable before termination. For this article, we are talking about our Cat5e internal ground shielded pass-through RJ45 plug. This plug even works with our bigger Cat5e shielded outdoor direct burial cable.

Recommendation? I suggest you watch the video and read this blog as both bring their own level of detail to the table.

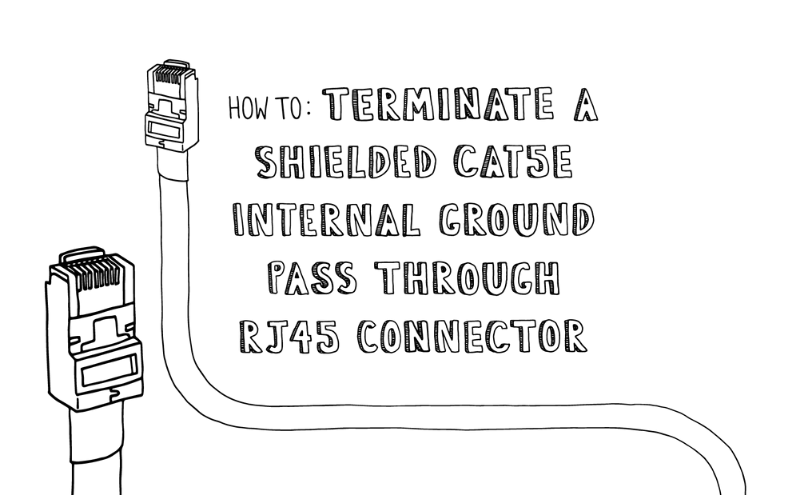

The primary features of this plug are:

- Ability to handle any trueCABLE Cat5e shielded cable

- Pass through in the design. Standard, solid-nose plugs can make life a bit harrowing for the installer with their "guess, cut, try" technique.

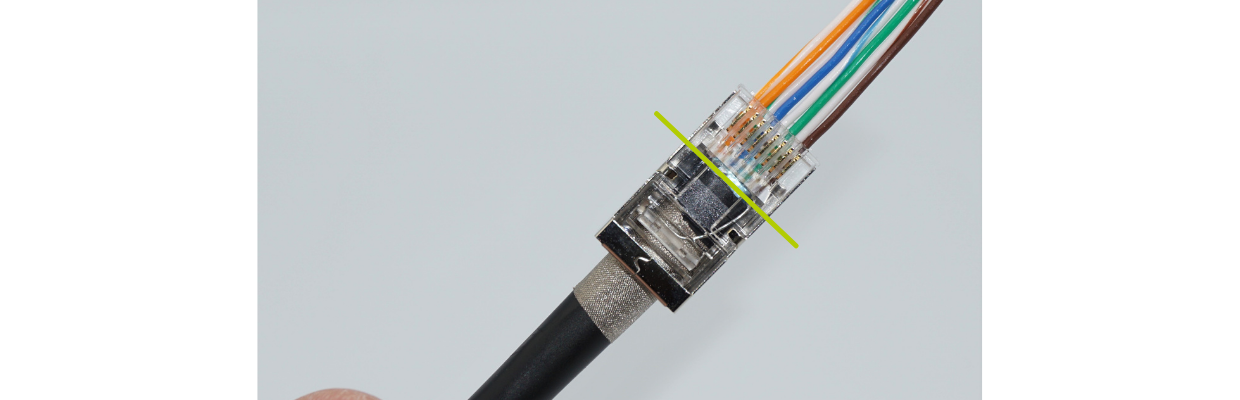

- Easy to bond your cable shield and/or drain wire to the metal plug housing

- Very well documented, so there is no guesswork on fitment.

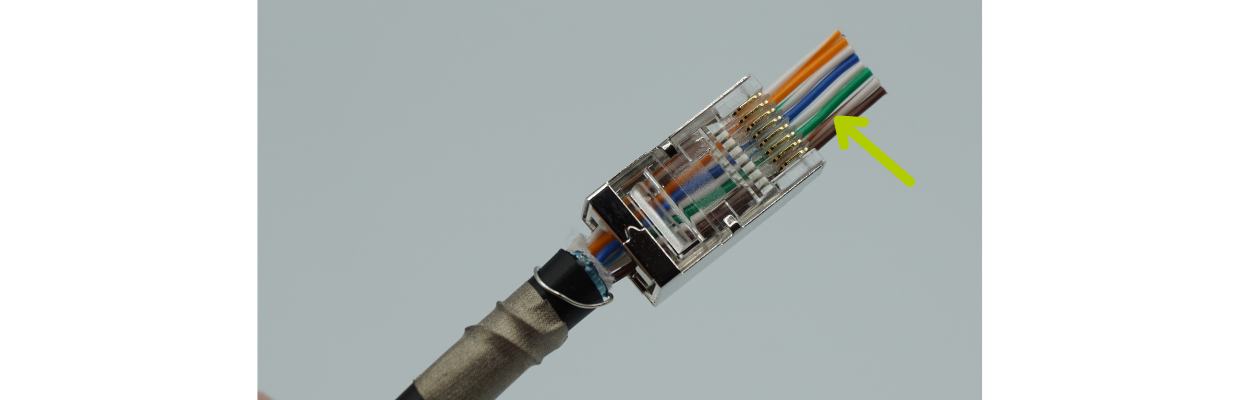

Metal bonding leafs on the rear inside of the plug

Can you use our Cat5e shielded internal ground plug on another manufacturer's cable? Sure, but first, you should make certain that your cable will fit onto our RJ45 plug. The whole "category" label is very misleading unless the cable and RJ45 plug are both made and tested by the same manufacturer, as is the case with trueCABLE. We stamp a Category on the bag because we go the extra step of confirming fitment and performance with our cable. If your Ethernet cable is of a different brand, you need to ensure fitment. A great resource is Selecting the Correct Connector.

For those who would like to understand more about RJ45 plugs and why there can be such a great deal of confusion surrounding them, please read What is an RJ45 Connector?

Enough of that! Let's jump right into terminating, shall we?

We will demonstrate this termination with trueCABLE Cat5e Shielded Direct Burial Ethernet cable. This cable has been fitment and performance tested when using our Cat5e Shielded Pass Through Plugs.

Tools you will absolutely need are:

- All-In-One trueCABLE RJ45 Crimp & Termination tool (trueCRIMP)

- Leave the strain latch presser bar set to ON (the tool comes this way from the factory)

- Flush cutter

- Optionally you can use the Cable Stripping & Cutting Tool -- our All-In-One Crimp and Termination Tool has a very good cable stripper on it but lacks a cable cutter. Any good cable cutter will work to cut your Ethernet cable.

Tools of the trade

Recommended tools to make your life a lot easier (and less painful):

- Light work glove (you only need one)

- A smooth metal shaft of some kind, like a screwdriver shaft

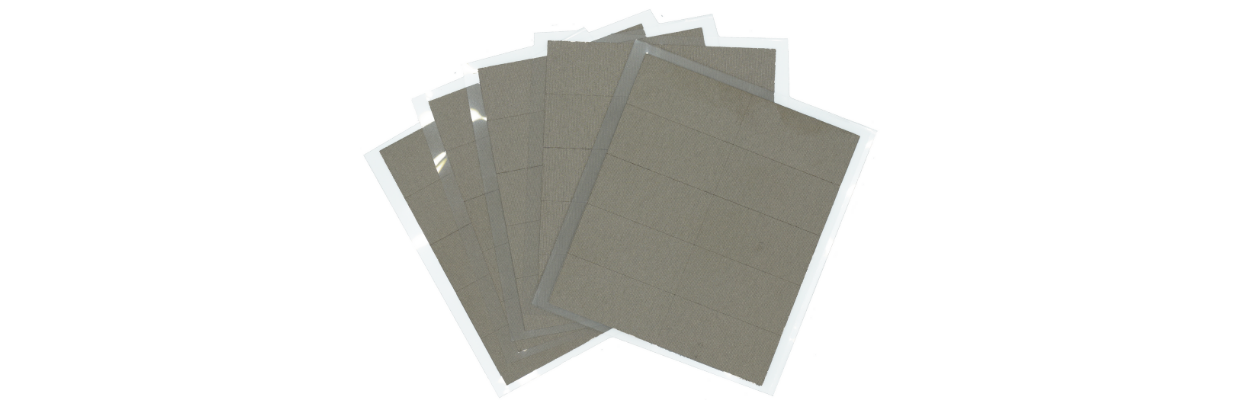

Recommended additional accessory to make termination of the cable shield a lot easier:

- Copper fabric strips. The copper fabric strips are copper-infused fabric with a permanent conductive adhesive. They are much tougher than plain copper strips and do not add to your cable's overall thickness!

Step 1: Cable Preparation

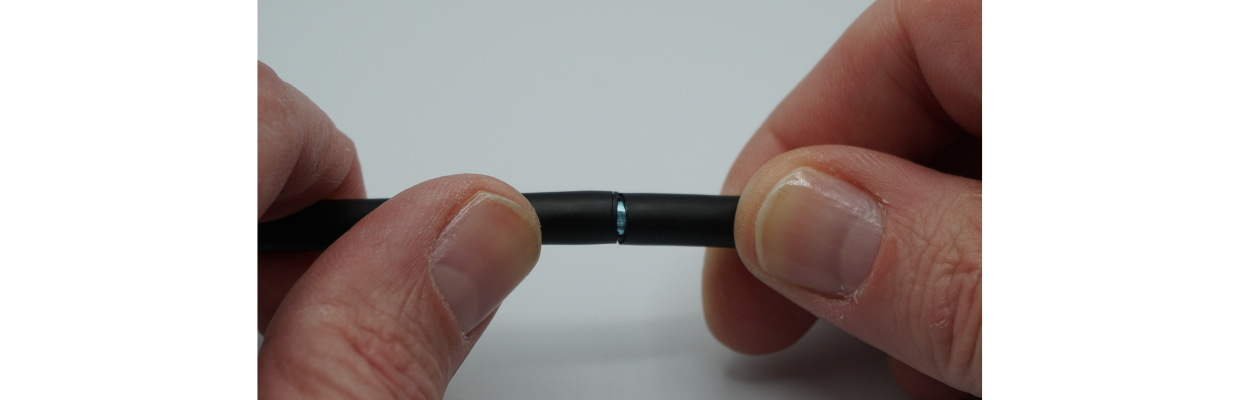

Using the built-in stripper on the All-In-One trueCRIMP tool for stripping the cable jacket...remove about 2.5" of the cable jacket.

- The built-in stripper is self-adjusting

- The size compatibility is 6.00mm to 8.00mm cable jacket OD, which covers everything from trueCABLE Cat5e Shielded Riser and thicker.

- It is helpful to roll the cable between your thumb and forefinger to make it more round prior to stripping. This reduces the chances of slicing the cable shield or nicking a conductor.

Now, pop the jacket open at the score and remove the jacket. Keep the jacket piece. It will be a free tool for at least five minutes. I promise.

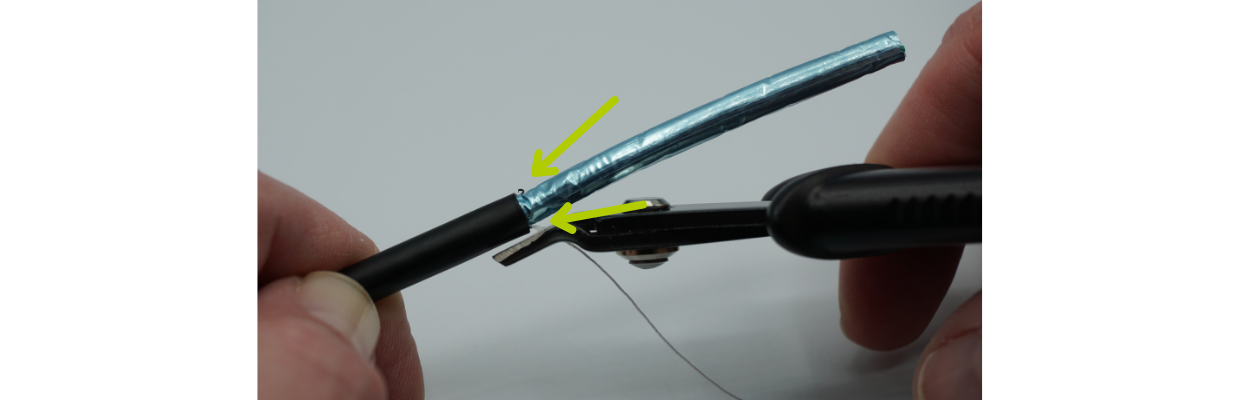

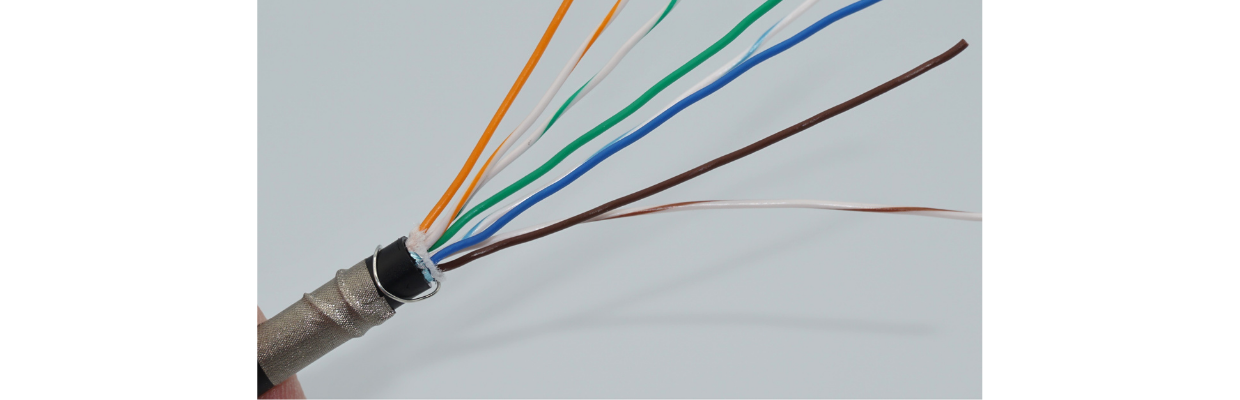

Peel open the cable shield. Make a tiny nip in the cable shield and remove it. Don't accidentally cut off the ESD drain wire in this process, as you will need it.

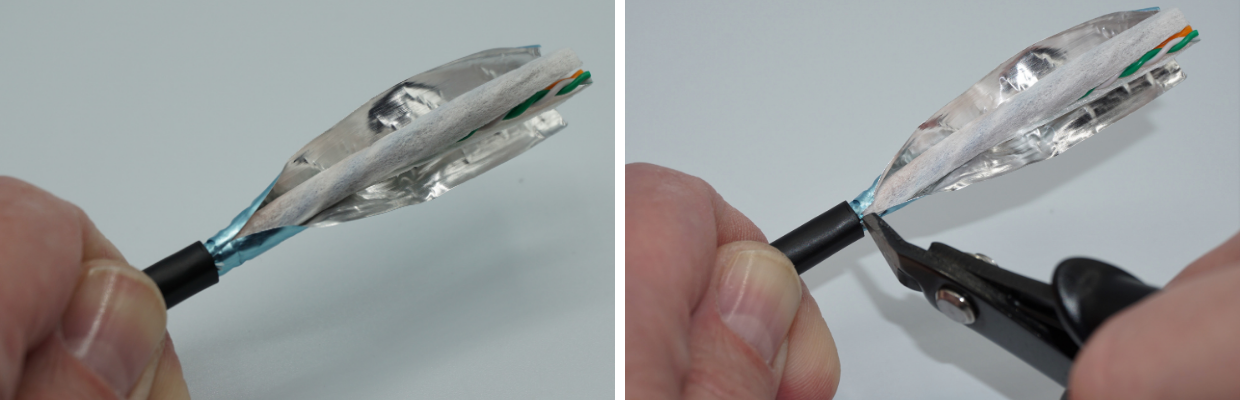

There are essentially two ways of bonding the cable shield to this internal ground plug. The first way is to NOT remove the cable shield but snip off the ESD drain wire. Fold the cable shield backward, and then you will use the cable shield as the bonding point. We will remove the cable shield and wrap the drain wire around the cable jacket and tack it down with one of the copper fabric strips for this demonstration. Either way will work, but the fabric strip makes it easier.

If you would like to see how this process works by using the cable shield for bonding instead of the drain wire and copper fabric strip, How To: Terminate a Shielded Cat6/6A External Ground Pass Through RJ45 Connector will give you a good demonstration of that technique.

Fully cut off the waterproof tape. Don't accidentally nick a conductor or cut off the ESD drain wire in this process!

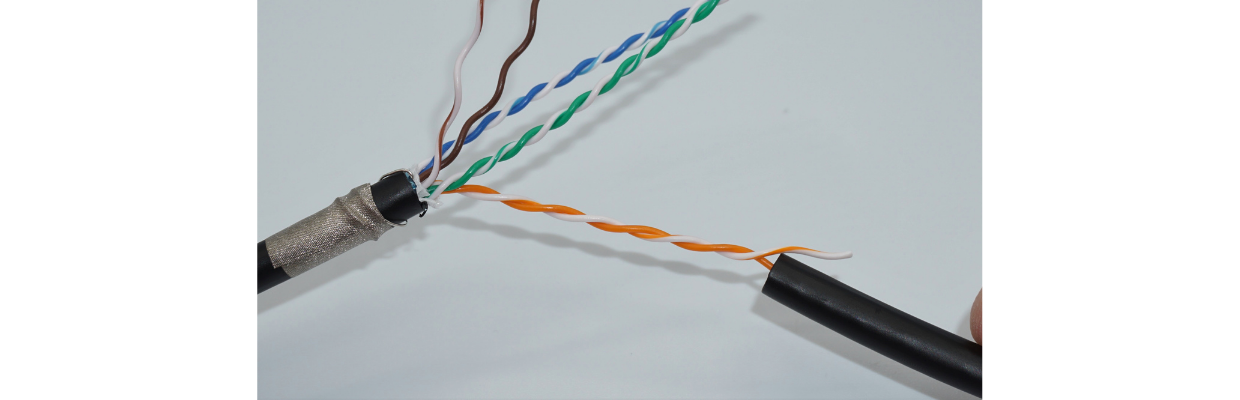

Step 2: Prepare Conductors

Untwist time. You can toss your free tool when done. Check to be certain the conductors are untwisted as much as practical, but not more than necessary. In other words, right down to the cable jacket but no further.

All untwisted...but how do you get the kinks out? Remember that glove and metal rod?

- The glove and metal rod will make this much faster and far less painful.

- Work the conductors individually, starting at the end of the cable jacket and going to the ends.

- Easy does it. Don't use too much pressure, as you are liable to remove the conductor insulation right off the copper.

- The straighter they are, the easier it will be for you to put the connector on

All straightened out. Ready to put into either T568A or T568B sequence.

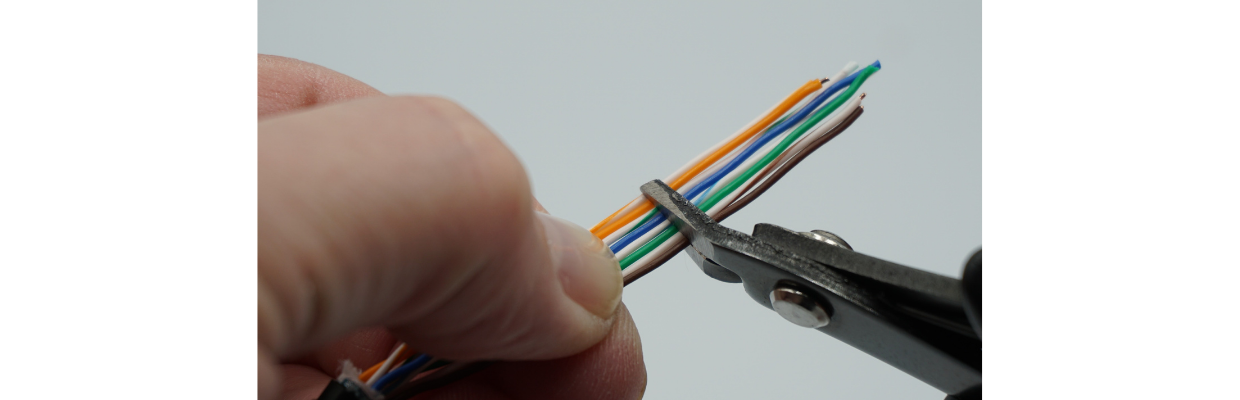

Put the conductors into the proper color sequence. I am using T568B. Keep the cable jacket area "clean" and neat. Less neat = more difficulty putting on the connector.

Locate a good spot, about 1.5 to 2" away from the cable jacket, to flush cut the conductors. T568B sequence shown. I like to work from the top down (if I can)—White-orange at the top and solid brown at the bottom.

- You can use either T568A or T568B for your sequence. One is not better than the other. Just be sure to use the same sequence at both ends of the cable unless you want to create a cross-over cable.

- Once you have those conductors lined up, keep pressure on them, so they don't get out of order on you. They will trust me. Try it once to see what I mean...

Here is a handy reference for you. When looking at the conductor color sequence, be sure you understand the orientation of the plug itself! Yes, it is quite possible to get the sequence correct and put the plug upside down. I have done it, so don't be a Don.

Step 3: Terminate

Insert the plug and cable assembly into the trueCRIMP tool. Use only light pressure and then press the tool lever fully downward.

Check to be sure all eight golden contacts are down and the conductors are fully flush cut.

Step 4: Admire & Check Your Work

Ready to plug in!

All done! So, there you have a Cat5e shielded internal ground RJ45 connector on your cable now. Go plug it in, and as always, HAPPY NETWORKING!

Wait!

Something not right? Your cable not performing your expectations? You could have a bad or poorly terminated RJ45 plug. Better check out What Does a Bad Termination Look Like?

trueCABLE presents the information on our website, including the “Cable Academy” blog and live chat support, as a service to our customers and other visitors to our website subject to our website terms and conditions. While the information on this website is about data networking and electrical issues, it is not professional advice and any reliance on such material is at your own risk.