Payment methods accepted

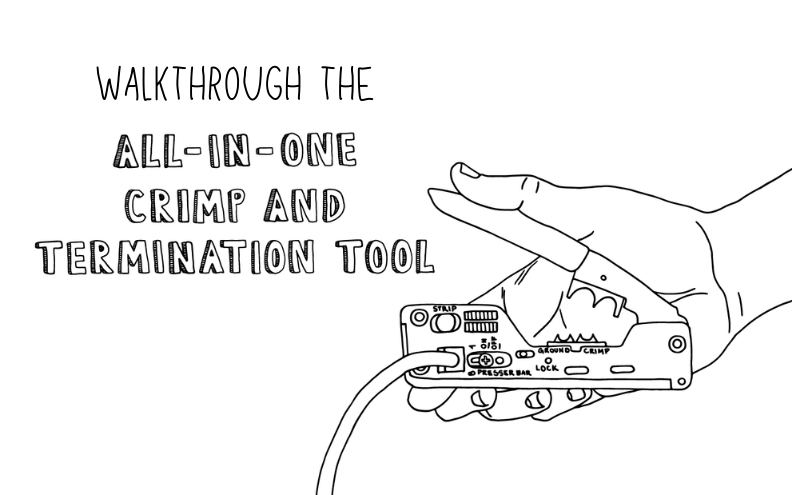

Walkthrough the All-In-One Crimp and Termination Tool | trueCRIMP

Written by Don Schultz, trueCABLE Senior Technical Advisor, Fluke Networks Copper/Fiber CCTT, BICSI INST1, INSTC, INSTF Certified

Are you looking for a simple yet effective method for terminating your Ethernet cables? While using a crimp tool is an effective approach, your choice of equipment matters.

Our All-In-One Crimp and Termination Tool performs multiple functions simultaneously. Very little maintenance is required to keep your tool in top functioning condition. It will provide you many years of service.

Top Choice for Ethernet Projects

- Capable of crimping and terminating any RJ45 plug (except proprietary RJ45 plugs like AMP or EXO-EX)

- Automatically cuts off conductor excess from pass-through style plugs, but works equally well with solid nosed standard plugs

- Adjustable strain latch presser bar to avoid crushing RJ45 plugs that do not have a strain latch (nor the rectangular cut-out for one)

- Dual external-ground-collar crimp cavities for multiple styles of shielded plugs and cable thicknesses

- TIA 568A and TIA 568B color sequences printed on the side of the tool

- Strips Ethernet cable from 6.00mm to 8.00mm jacket OD -- giving you the perfect score every time

- Sliding gun lock keeps the tool closed when not in use, and is easy to operate with one hand

- Bright green accents so it does not disappear into your tool bag

- Strong and long-life internal components

- Replaceable conductor flush cut blade

- Rust-resistant steel oxide construction

- Forever Warranty

With all these features, it’s hard to imagine using any other terminator tool for the job. Here are some tips for using a crimp tool in your network setup.

Tool Walkthrough

Front view. Notice the external ground crimp cavities, cable jacket stripper, and adjustable strain latch presser bar..

Back view. Here you can see the flush cut mechanism that shaves off excess conductors from pass-through plugs.

Unlocked

The crimp cavity, adjustable strain-latch presser bar, stripper, and T568A/B color code diagram

Strain latch presser bar being adjusted to the “OFF” position. You can adjust it between "ON" and "OFF" by backing out the screw four turns and then raising or lowering the bar. Don’t fully remove the screw and lose it. It is not captive. Screw back down firmly when adjustments are made. (By default the presser bar is set to "ON")

The strain latch presser bar is set to ON (to engage) out of the factory. Use the ON setting for all trueCABLE plugs. This functionality is provided for maximum versatility if you come across RJ45 plugs that do not have a strain latch.

Just in case you were wondering what a strain latch is, and how it works...

Stripping an Ethernet cable. Due to design limitations, this stripper handles 6.00mm to 8.00mm cable jacket ODs. This illustrates why we also carry our Cable Stripping & Cutting Tool, which can handle ANY cable jacket OD, and can cut cable as well.

Crimping an external ground collar on a shielded plug

In most cases you need to use the larger cavity as a “start” cavity and then switch over to the smaller “finish” cavity in order to make a fully formed crimp. There is no exacting formula for this, and is a judgement call.

The result is a perfectly formed crimp. You don’t want to over or under crimp the collar.

Basic Maintenance

After each use:

Wipe down the exterior metal surfaces with a small amount of high-quality preservative oil, or a silicone “gun and reel” cloth.

Twice a year or quarterly for heavy usage:

Oil the indicated lubrication points. Use only one drop of oil at each point. A high-quality, firearms grade PTFE bearing lubrication and preservation oil is recommended.

Lubrication point at the handle. Use one drop of oil only on the pin, on either side of the linkage. A needle oiler is a great help with this lubrication point.

Second linkage lubrication point. One drop of oil on either side of the link, on the pin itself, is all that is necessary.

Conductor Flush Cut Blade - Replacement

The flush cut blade that removes conductors from the nose of the RJ45 plug is replaceable. First, lock the tool and use a Phillips screwdriver to back out the screw. Now, unlock the tool to lower the presser bar and termination teeth. Using a rod or other thin, rigid tool inserted from the opposite side, tap until the blade assembly is dislodged from the locator roll-pin found below the screw. Once the blade assembly has been pushed off, put a fresh blade assembly onto the locator roll-pin. Replace the screw and tighten down firmly.

Fully CLOSE and lock the tool handle. Using a Phillips screwdriver, back out and remove the screw. Note there is a roll-pin still holding the blade onto the tool.

Turn the tool over. OPEN the operating handle. Carefully tap the flush cut blade off of the roll pin. Do not accidentally contact the termination teeth in the process, as you may ruin them. A wooden dowel is the safest tool to use!

Screw and blade removed. Replace by tapping a new blade onto the roll pin and tightening the screw down firmly. Dispose of old blade.

Do not dispose of the old blade carelessly. A “dull” blade is still more than sharp enough to cut you or others. Place the blade onto the tacky side surface of a piece of duct or heavy electrical tape and wrap several times so the edge is not exposed. Dispose of carefully.

If you notice that the flush cut blade is shaving off the actual plastic of the plug, try reducing the pressure used to insert and hold the plug/cable into the crimp cavity during the crimp operation. Light pressure is sufficient, and you may stop holding the cable after the strain-latch presser bar begins passing into the rear of the RJ45 plug during the termination process. The strain-latch presser bar will “lock” the plug into the correct position during the procedure.

There is our All-In-One Crimp and Termination Tool in a nutshell. With our terminator tool at your disposal, you’ll have equipment you can count on. Treat this tool well, and it will serve you for years to come!

HAPPY NETWORKING!

Don, Will the TrueCable AIO crimper work with Ubiquiti/UniFi ToughCable TC-GND. Those RJ45 ground connectors have a wire riveted to the plug that does not fit normal crimpers. Thank you.

Hello! Nope, that plug only works with a specific crimp tool and I don’t know which one. It won’t work with ours or any standard / passthrough RJ45 crimper.

The video does not show how the shield connection is properly executed using this tool. Shielded connectors must have the drain wire, or part of the braid if there is one, tucked between the cable jacket and the strain relief to ensure electrical contact between the cable shield and the metal housing of the connector. Otherwise the shield is not locally connected to anything, defeating much of the shield's purpose which is to direct noise currents flowing on the shield away from the inner conductors. Without the shield connection, noise currents on the shield are capacitively coupled to the inner conductors, causing increased noise on the wires and possibly higher bit-error rates. Another purpose of the shield is to control noise radiated from the wires, which also relies on a proper shield connection.

Hello! The cable termination demonstrated in the video was for U/UTP. There was no shielded cable shown. That said, we do have plenty of content around proper termination of shielded Category cable in our Cable Academy. As for the drain wire and cable shield termination, all that is required to terminate the cable shield is in fact the drain wire. We currently sell a copper conductive adhesive fabric strip where it is used to tack down the drain wire (after being wrapped around the cable jacket cut end) and at the same time this provides a broad bonding surface. The cable shield itself is removed in this process, utilizing the drain wire only. In our shielded Category cable, the tinned drain wire makes full length contact through the cable with the conductive side of the cable shield. The old method (a still valid one) would be to fold back the cable shield and wrap the drain wire around it to terminate the cable shield to the termination hardware, but quite frankly that method is more trouble than it is worth when working with 8P8Cs (although not much of an issue with IDC terminations such as patch panels and keystones). I hope that helps clear things up!